ICT can offer off-line samples control machinery for waviness measurements

(in µm/sec)

As for the bearing noise, also the waviness of bearing rings’ grooves and of steel balls can be performed basically through 3 different measurement methods:

As for the bearing noise, also the waviness of bearing rings’ grooves and of steel balls can be performed basically through 3 different measurement methods:

- By Acceleration (dB), very sensible to high frequency deviations (e.g. roughness and surface defects);

- By Displacement (µm), very sensible to basic geometrical errors, i.e. poligonalities of low order (e.g. ovality, triangularity, etc.);

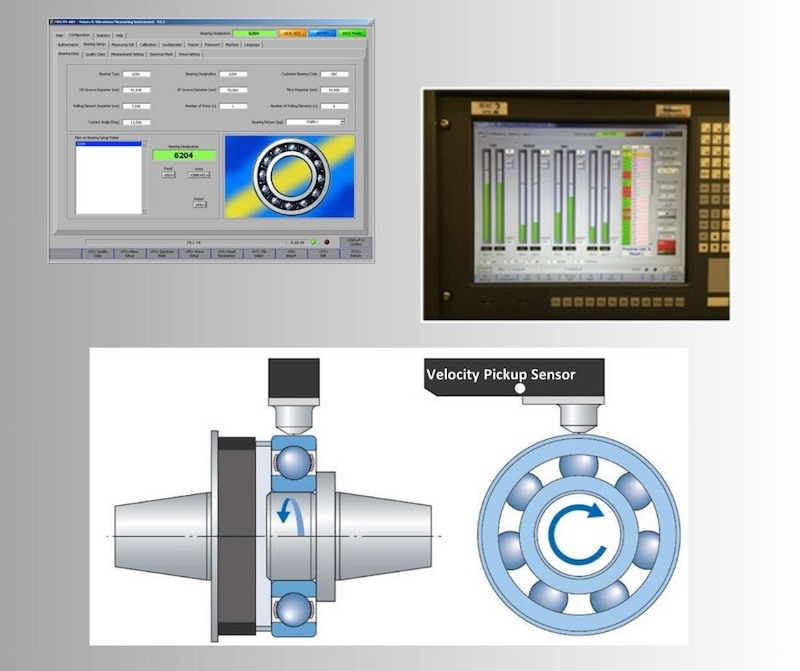

- By Velocity (µm/sec), i.e. the best method able to detect with good resolution geometrical errors in the whole range of frequencies.

The velocity approach was developed many years ago by SKF to overcome the problems of the other two methods and it has been used both for noise measurements and for waviness controls.

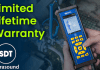

We can offer the Italian technology of waviness measurements machines in velocity, both for rings grooves (VKR) and for balls (VKL). Both these control machines have the advantage to provide fast and reliable feedback about the waviness quality of the components, directly in the manufacturing shopfloor environment, regardless the vibration level of the production lines. Easy to use by the operators for samples inspection, they are much less expensive than the sophisticated laboratory equipment of competitors (that indeed often can be used only in closed laboratory) and provide excellent indications if the manufacturing process is really under control or not.

Besides the possibility to set the “traditional” L, M, M1 and H bands, VKL and VKR of Ict allows also to set-up customized spectrum masks to detect specific types of defects of the product under control. Ict can also provide the velocity pick-up sensors as well as the equipment for the periodical calibration of pick-up at the different testing frequencies.

For more info about our products offer for bearing rings and balls waviness equipment, please get in touch with us writing to info@consulting-trading.com or calling at +39 (0)121376811.